- gzk@hnlcalloy.com

- +8615737205888

- Qugou Town, Anyang City, Henan Province

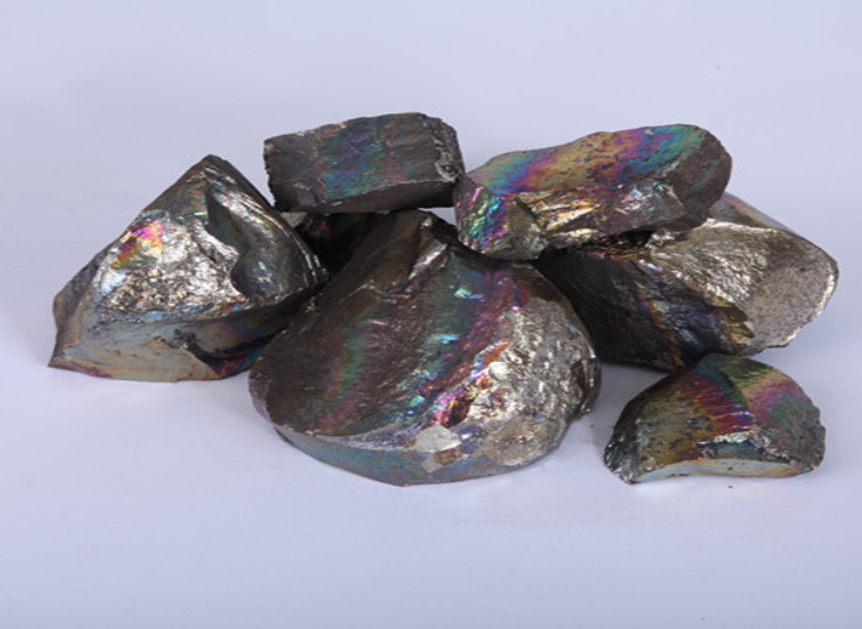

The extraction methods of manganese metal mainly include thermal method (fire method) and electrolytic method (wet method). Electrolytic metal manganese), its purity can reach over 99.7~99.9%. Nowadays, electrolytic production has become the main method of manganese metal production.

The extraction methods of manganese metal mainly include thermal method (fire method) and electrolytic method (wet method). Electrolytic metal manganese), its purity can reach over 99.7~99.9%. Nowadays, electrolytic production has become the main method of manganese metal production.

Manganese and manganese alloys are one of the indispensable raw materials in the steel industry, aluminum alloy industry, magnetic materials industry, chemical industry, etc. Manganese is an indispensable additive in the smelting industry. After electrolytic manganese is processed into powder, it is the main raw material for the production of manganese tetraoxide. The original magnetic material widely used in the electronics industry is produced from manganese tetraoxide. The electronics industry, metallurgical industry and The aerospace industry requires electrolytic manganese metal. With the continuous development of science and technology and the continuous improvement of productivity, electrolytic manganese metal has been successfully and widely used in iron and steel smelting, nonferrous metallurgy, electronic technology, chemical industry, environmental protection, Food hygiene, welding rod industry, aerospace industry and other fields.

|

Brand |

Mn |

C |

Si |

Fe |

P |

S |

Ni |

Cu |

Al+Ca+Mg |

|

|

≥% |

≤% |

|||||||

|

JMn97 |

97.0 |

0.08 |

0.4 |

2.0 |

0.04 |

0.04 |

0.02 |

0.03 |

0.07 |

|

JMn96 |

96.5 |

0.1 |

0.5 |

2.3 |

0.05 |

0.05 |

0.02 |

0.03 |

0.07 |

|

JMn95 |

95.0 |

0.15 |

0.8 |

2.8 |

0.06 |

0.05 |

0.02 |

0.03 |

0.07 |

|

Size: the most large not more than10 kg, the number of less than10 mm*10 mm is no more than 10% of the total weight 10 mm to 50mm is more than 90% ( particle size may be based on customer demand) |

|||||||||

The main products include rare earth magnesium ferrosilicon alloy (spheroidizing agent), nucleating agent, pipe powder, ferrosilicon (particles), (high, medium and low) carbon manganese, (high, medium, low and micro) ferrochromium, alloy cored wire, silicon carbide, silicon nitride, slag onglomeration agent, desulfurizer, and carburant, as well as other customized alloy products.