- gzk@hnlcalloy.com

- +8615737205888

- Qugou Town, Anyang City, Henan Province

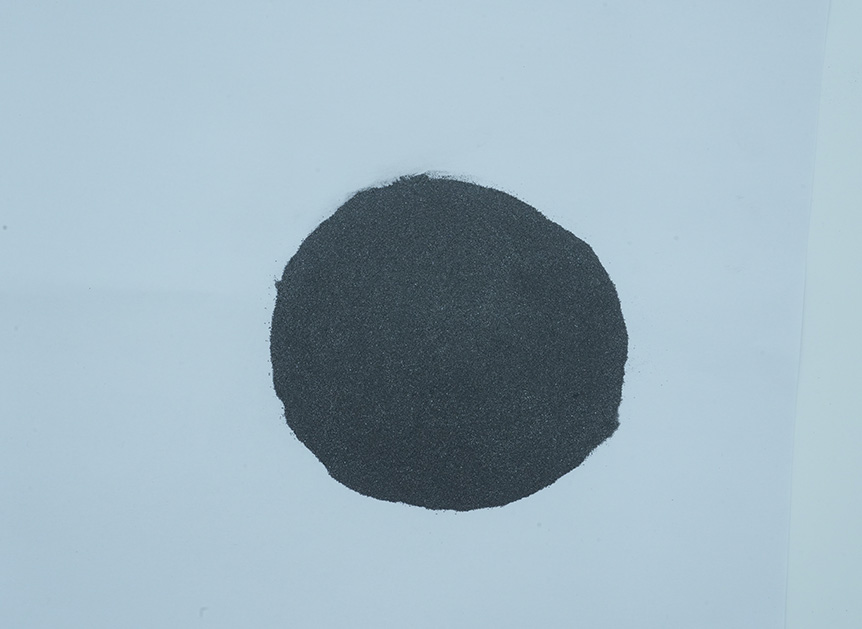

Pipe powder is a ferrosilicon-based composite material with strictly controlled alloy elements and particle size. It can effectively reduce the degree of supercooling, inhibit the formation of carbide, slow down the decay time, and has a slight sensitivity to the casting size, showing a consistent nucleation effect.

Pipe powder is a ferrosilicon-based composite material with strictly controlled alloy elements and particle size. It can effectively reduce the degree of supercooling, inhibit the formation of carbide, slow down the decay time, and has a slight sensitivity to the casting size, showing a consistent nucleation effect.

The pipe powder can strengthen the nucleation instantaneously and remove the pores and pinholes on the outer surface of the cast pipe. When the inner surface of the pipe mold is severely cracked after using for a long time, zinc powder and aluminum powder can be added to the pipe powder to avoid the difficulty in pipe drawing. The pipe powder also plays the role of tertiary nucleation and prolongs the service life of the pipe mold.

Pipe powder is a ferrosilicon-based composite material with strictly controlled alloy elements and particle size. It can effectively reduce the degree of supercooling, inhibit the formation of carbide, slow down the decay time, and has a slight sensitivity to the casting size, showing a consistent nucleation effect. Pipe powder has a unique effect in eliminating the pores of cast pipe.

The pipe powder can strengthen the nucleation instantaneously and remove the pores and pinholes on the outer surface of the cast pipe. When the inner surface of the pipe mold is severely cracked after using for a long time, zinc powder and aluminum powder can be added to the pipe powder to avoid the difficulty in pipe drawing. The pipe powder also plays the role of tertiary nucleation and prolongs the service life of the pipe mold.

It refers to the silicon barium alloy grinding powder used in the pipe mold, showing a sound effect on the surface treatment of castings.

|

Specification |

Si |

Al |

Ca |

Mn |

Zr |

Ba |

Moisture |

Size (mm) |

|

DN80-150 |

60-69 |

0.8-1.5 |

2.0-4.0 |

1.0-3.0 |

2.5-3.5 |

4.0-8.0 |

≤0.5

|

0-0.3 |

|

DN>150 |

60-65 |

<1.5 |

4.0-6.0 |

<0.5 |

0.5-2.5 |

4.0-6.0 |

||

|

DN>450 |

60-69 |

<1.5 |

4.0-8.0 |

<0.5 |

|

4.0-6.0 |

The composition can be adjusted according to customer requirements

30-325 mesh 25kg woven bag with moisture-proof inner membrane or 1-ton or 0.5-ton outer bags/plastic woven bag, or other packages as required by the customers. Various trace elements are supplied.

Packaging and particle size: 25 kg plastic woven bag with moisture-proof inner membrane, customized particle size, and various trace elements are supplied.

The main products include rare earth magnesium ferrosilicon alloy (spheroidizing agent), nucleating agent, pipe powder, ferrosilicon (particles), (high, medium and low) carbon manganese, (high, medium, low and micro) ferrochromium, alloy cored wire, silicon carbide, silicon nitride, slag onglomeration agent, desulfurizer, and carburant, as well as other customized alloy products.